Wastewater Reuse (MBR)

The Dunwell Membrane Bio-Reactor (DMBR) system adopts biochemical reaction and membrane separation technologies to treat municipal or industrial sewage. It produces high quality effluent for reuse purposes such as irrigation, flushing or facility washing. DMBR allows you to bid farewell to the problem of poor sedimentation and the huge capital cost of acquiring secondary clarification tanks often associated with the conventional activated sludge process.

DMBR is deliverable in the form of wastewater treatment plant and a compact containerized system — the Dunwell Membrane Bio-Reactor Containerized Plant (DMBR-C). Predesigned and skid-mounted, DMBR-C can be offloaded quickly and efficiently at your wastewater treatment site to perform solids screening, secondary and tertiary wastewater treatment with a single containerized package.

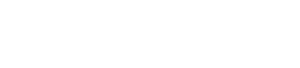

How it works

DMBR uses a membrane to filter wastewater through the separation of activated sludge (bacteria) and treated effluent. With pore sizes of 0.04 micron (for reference, the size of E.coli is 0.45 micron), the membrane surface is exceptionally effective in separating bacteria and organic matters from the treated effluent.

Our design follows Hong Kong public works – DSD, EMSD and EPD design guides and features dual PLC controllers and uninterrupted power supply for control.

Applications

- Dunwell Membrane Bio-Reactor (DMBR) Wastewater Treatment Plant

- Domestic wastewater treatment / greywater reuse in hotels, residences and commercial buildings

- Industrial wastewater treatment such as landfill leachate, high BOD food processing wastewater, livestock wastewater, chemical wastewater, pulp and paper wastewater

- Water reuse or recycling

*Environmental Permit application included for sewage reuse *

- Dunwell Membrane Bio-Reactor Containerized Plant (DMBR-C)

- Golf course / resorts

- Coastal discharges

- Environmentally sensitive areas such as Special Areas of Conservation (SACs) and salmonoid waters

- Ground water sensitive areas

- Retrofits to existing wastewater treatment plant

- Bio-toilet / Bio-toilet — containerized system

Benefits

- Small footprint: requires at least 30% less space than conventional treatment processes, reducing capital cost

- High separation efficiency and biomass concentration (10,000–20,000 mg/L)

- Unmatched effluent quality: with a greatly increased removal rate of COD, BOD, nitrogen and phosphorus, effluent is free of suspended solids and suitable for reuse or direct discharge

- Long solid retention time, which can greatly reduce sludge wastage

- Easy to install, operate and maintain (all mechanical equipment has standby units), greatly reducing operational costs and energy consumption

- Reduced fouling and increased water flux

- Fully automatic remote monitoring and control to provide 24-hour surveillance

- Excellent support from Dunwell: service team on standby 24/7; technicians arrive on site within 2 hours of call (Vehicle-accessible areas only)

- Plus these additional advantages of a Containerized MBR system:

- Modular design enables phased construction of wastewater treatment plants, adaptable to a wide range of sizes and flow rates

- Compact design, easy to relocate

- Short delivery period: factory installed and tested (ie, no on-site construction)

- Minimal operation attention

Job References

Modular DMBR in Japan

Capacity: 10 m3/day

Size: 6 m x 3m x 2.2m (H)

Configuration: EQT+ MBR + UV

Application: Toilet Sewage Treatment & Reuse for flushing

Modular DMBR for Pok Oi Kong Ha Wai Village (Transitional Housing)

Capacity: 200 m3/day

Size: 12 m x 3m x 2.2m (H) x 5 sets

Configuration: MBR + UV + Chemical Phosphate Removal

Application: Toilet Sewage Treatment